About us

Our company, Vilex 94 Kft, has been one of the dynamically developing companies in the eastern region of Hungary since 1994.Thanks to our specialists, quality management system and equipment park developments, we process 1,500 tons of steel yearly, which constantly growing.

Services

Production and construction of steel halls

We product, construction and on-site assembly of steel buildings.

Welding

Acid-resistant steel welding, aluminum welding, carbon steel and stainless steel welding. Manual welding of unique steel structures.

CNC Plasma cutting

With our CNC-controlled plasma cutting equipment, we also cut carbon steel and highly alloyed steel up to a sheet thickness of 50 mm. The size of the cutting table is 6000x2000mm

Edge bending

Edge bending of steel, stainless steel and aluminum sheets is done with our CNC-controlled 4-axis machines and with the help of our trained professionals, from small individual pieces to large series production.

Roller

With our rolling machines, we roll regular cylinders, cones and arcs with variable radius and arbitrary geometry The steel profiles are rolled to the desired size with a manual or CNC-controlled bending machine.

Sheet cutting

With our sheet metal cutter, we can cut steel sheets to the required size from 0.5 mm to 20 mm in length of 3000 mm.

Work processes

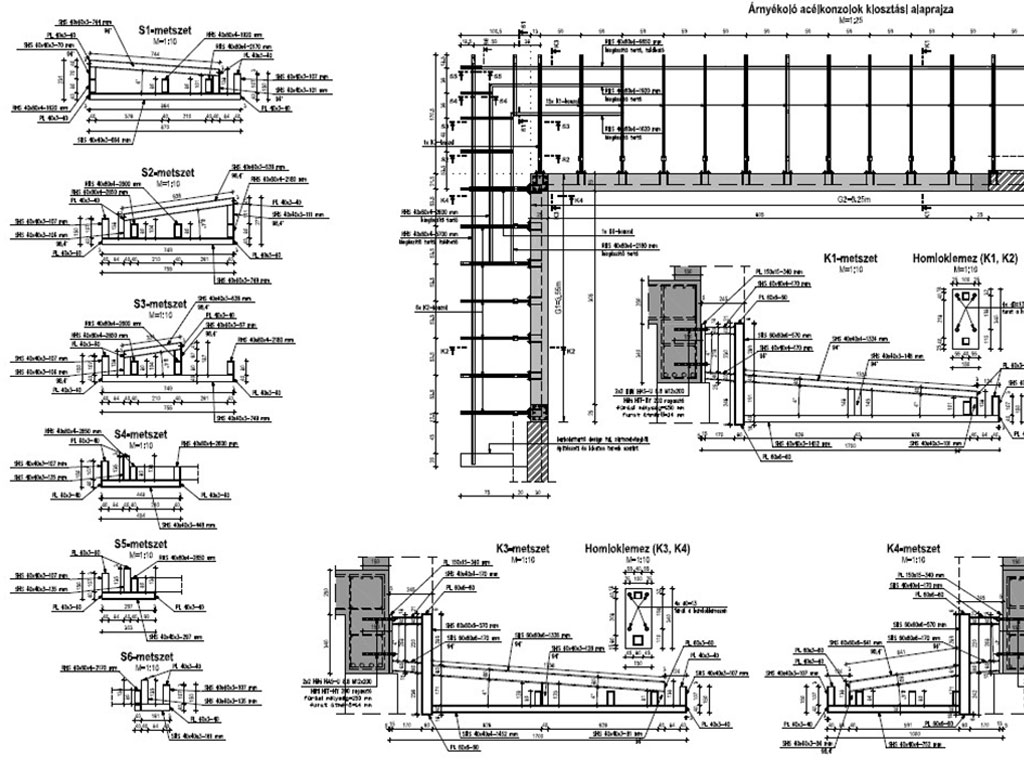

Planning

With modern design programs and well-prepared design colleagues, we undertake the design of steel products, from the steel structure of buildings to agricultural and earthwork machine parts to all other metal products.

Preparation

Thanks to our stock of raw materials, most of the time, our production processes can be started quickly from the material which is already in stock.

With the help of our cutting machines, our skilled employees cut the plates and profiles to the desired size. Then we also perform other necessary work processes, such as edge bending, drilling, or rolling.

Production

Thanks to our employees with many years of expertise, production is not only fast, but also precise.

For our customers, we are ready to produce complete metal parts or assembled surface-treated, packaged final products.

Workmanship

During workmanship, the manufactured steel structure is delivered to the site and installed in the desired location with the help of measuring instruments.

Our works

Production and construction of steel halls

We product, construction and on-site assembly of steel buildings.